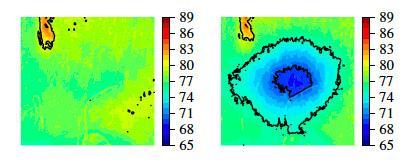

In this project, we perform drop-impact experiments and conduct numerical and CFD simulations to explore the effect of a Phase Change Material (PCM) on the transient heating of a cold liquid drop impacting a heated substrate. The objective is to develop new techniques for enhancement of phase change heat transfer in industrial applications.

The physics of the transient behavior of liquid drops impacting hot or cold surfaces are of significance in many different applications such as spray cooling, aircraft icing, etc. Further, the transient heating and cooling of vapor spots and liquid patches is of significance in determining the heat transfer performance parameters in phase change processes such as boiling and condensation. The thermal transients in all these processes are primarily dictated by the passive thermal properties of the solid substrate (e.g. thermal conductivity, specific heat) and by the flow conditions. An active control (or manipulation) of these ultra-fast thermal transients could provide a means to enhance the performance parameters in various phase change-based heat transfer processes. In this project, we use experimental and computational techniques to explore the effect of a solid-liquid phase change material (PCM) on the thermal characteristics of a liquid drop impacting a hot surface. High-speed optical and infrared imaging techniques are employed for visualizing the flow and measuring the temperatures, respectively. A numerical model is being developed to explain the effect of the PCM on the thermal transients in the liquid drop and the solid substrate. The insights obtained from these findings can have a significant impact on several technologies in the areas of phase change-based heat transfer and thermal management.